Piano Restoration

Piano Restoration

Restoration In A Nut Shell

Nut Shell

Restoration Options

Refinishing

To include all woodworking, case and veneer repairs. Dress and repair all gouges, splits and scratches. Remove piano hardware (hinges, pedals, locks, caster) polish and buff or re-plate if necessary in nickel or brass. Hand strip and remove old finish and stain. Hand sand and prepare veneers for staining to the color of your choice. Finish piano in bar-top lacquer with 12-15 coats to a fully closed grain finish. Hand sand between coats to a glass smooth finish with no grain valleys or bumps. Replace all decalcomania-historical decals are exactly matched. Hand rub finish to a traditional satin finish

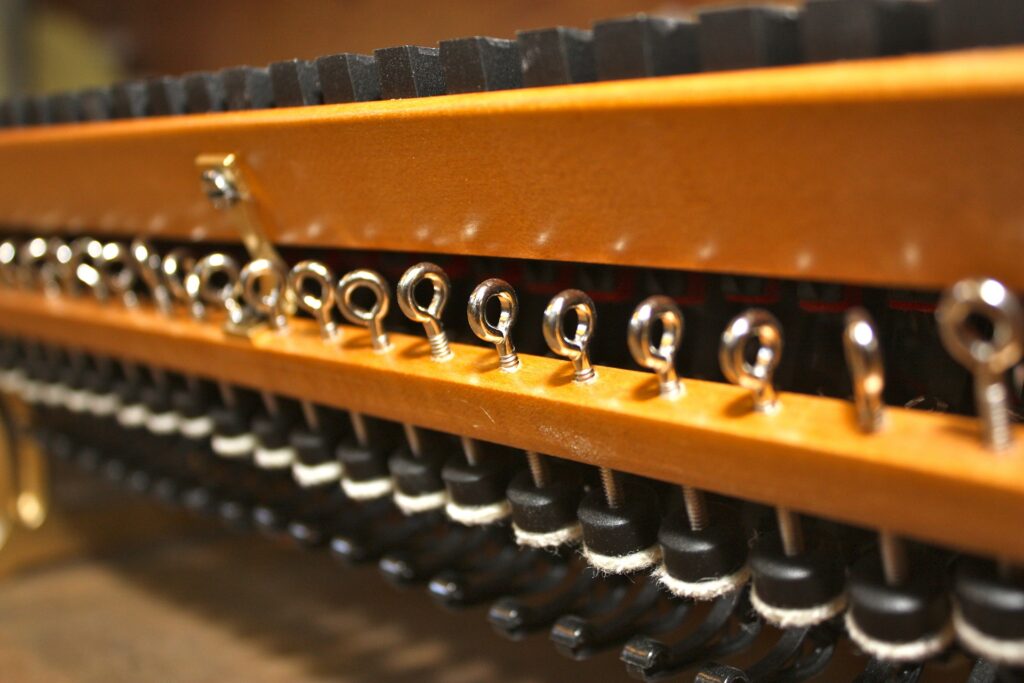

Action Rebuilding

To include: New hammers-custom bored to match originals, new shanks, hammer butts and flanges are exactly matched. Install new wippens. Remove and replace all key bushing cloth. Replace and regulate backchecks. Repair all action springs. Replace keybed cloth throughout. Voice hammers. Perform Major regulation of all action components and restore it to factory specifications. Rebuild and regulate pedal and trapwork system and regulate dampers.

Restringing

Repair soundboard-board is dried and shimmed, crown is restored, historical decals on the board are exactly matched and replaced, the the entire board is finished in lacquer. Bridges are repaired, notches are re-cut, new graphite is applied and the bridge is then finished. The metal plate is washed, sanded and and then gilded in bronzing powders. Plate lettering and artwork is applied and then the plate is finished in lacquer. The string bearing is set to factory specifications and new strings that exactly match the originals are installed. New tuning pins are installed. All damper felts are replaced with new duplicates. The damper guide rail is re-bushed. Multiple tunings are performed.

Before

After

Our Services

© 2024 Burton & Wilson | All Rights Reserved